Power electronic modules are key components for energy generation, energy distribution and energy application and play a significant role in electromobility for the provision of energy in the vehicle and at the vehicle drive. The service life and energy efficiency of these modules significantly determine the efficiency and economic success of the process in which the module fulfils its function. State-of-the-art assembly and connection technology is the solution to today’s problems in the production and application of power electronic assemblies.

However, it is precisely this assembly and connection technology that is difficult to implement, both for SMEs and for large companies that are new to manufacturing, because considerable resources have to be invested in process development.

The aim of the ProMuPower project at Kiel University of Applied Sciences is to develop a new type of circuit carrier including a flexible manufacturing process. Tresky, as a specialist for sintering technologies as assembly and connection technology for power modules, is part of this project. The flexible manufacturing process is intended to lower the entry barrier for users and increase functionality. The new innovative assembly and connection technology enables large-area, temperature-resistant, low-inductance and temperature-conductive connections of electronic power modules for e-drives. The 48-volt demonstrator developed in the project shows these advantages very clearly. Its field of application is mild hybrid drives in road vehicles, but also drives of industrial trucks and servo drives. Future customers of this solution will be offered not only a component but, if desired, the entire production flow consisting of joining material, pick & place component positioning, joining machine, process specification and validation method.

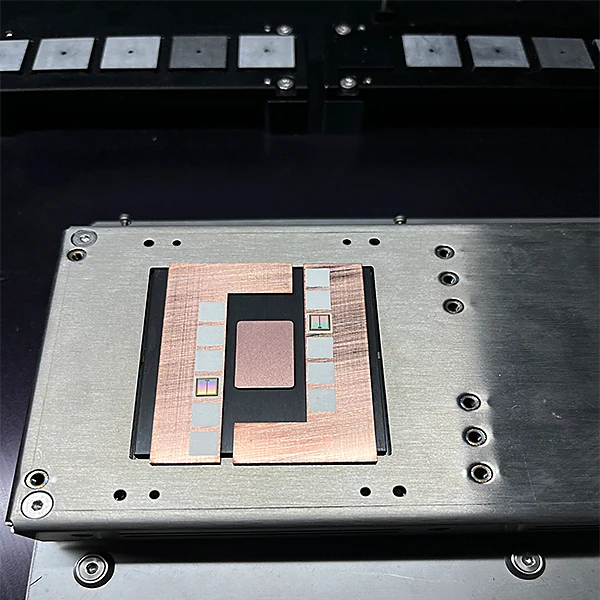

In the ProMuPower project, a special pick & place component positioning is being developed in the form of an innovative production technology, an organic joining material (TIM film) and a joining method (lamination). In this way, multifunctional power substrates with thick copper conductor layers and integrated temperature and current sensors are created. The thermally very effective thermal interface film (TIM film) is electrically isolating and allows thick copper assemblies without thermomechanical stress in the layers. The more robust construction of the new power modules ensures long-lasting and energy-efficient products. This enables a significantly more economical production and an increased lifetime and power density of power modules compared to production with ceramic circuit carriers. The novel process is environmentally friendly, as the circuit carriers are produced by means of special individual assembly and the required conductor track layout is created by stringing together copper function plates, some of which are already equipped with sintered (semiconductor) components. These thick copper conductor plates are created by stamping or laser separation without the need for any chemical processing steps.

The Institute of Mechatronics at Kiel University of Applied Sciences focuses on three central tasks: the academic training of tomorrow’s engineers, knowledge transfer between the university and industry, and acting as a think tank for innovative applications that push the boundaries of power electronic assemblies. A team consisting of students and experienced staff work on various power electronics projects. The ProMuPower project will be presented at PCIM Europe 2023 in Nuremberg, from 09 to 11 May by Kiel University of Applied Sciences in Hall 6, booth 210. Tresky will also be presenting itself at PCIM in Hall 6, Stand 434.