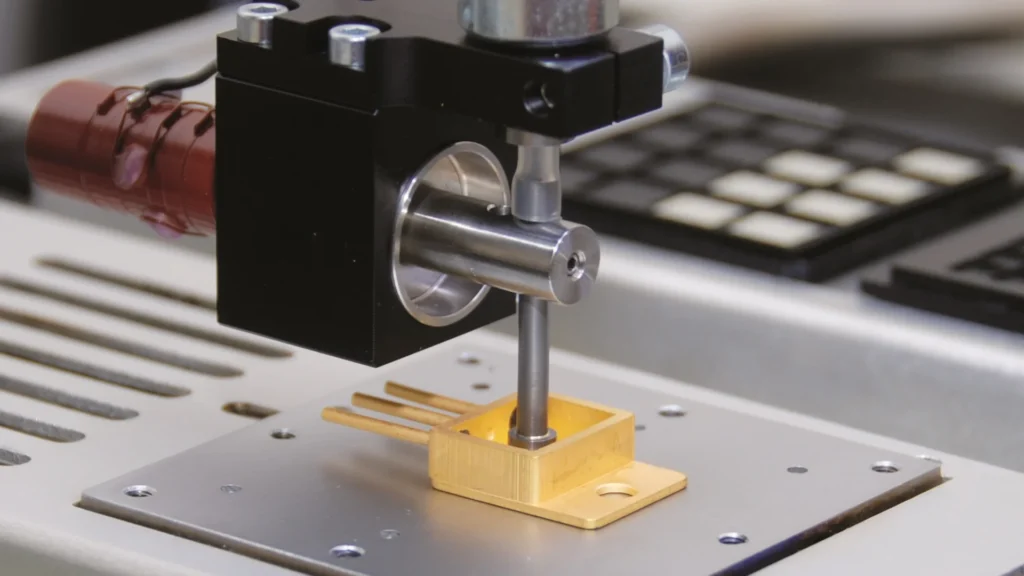

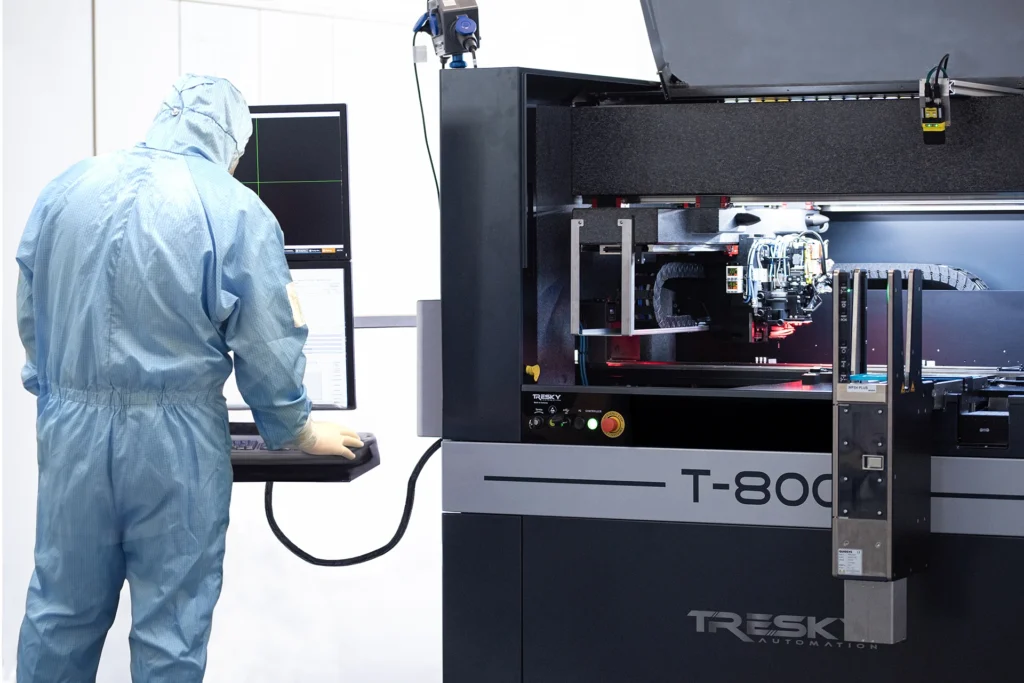

DIE Bonder

for R&D and Production

Made in Germany

Our latest white paper on metallic sintering.

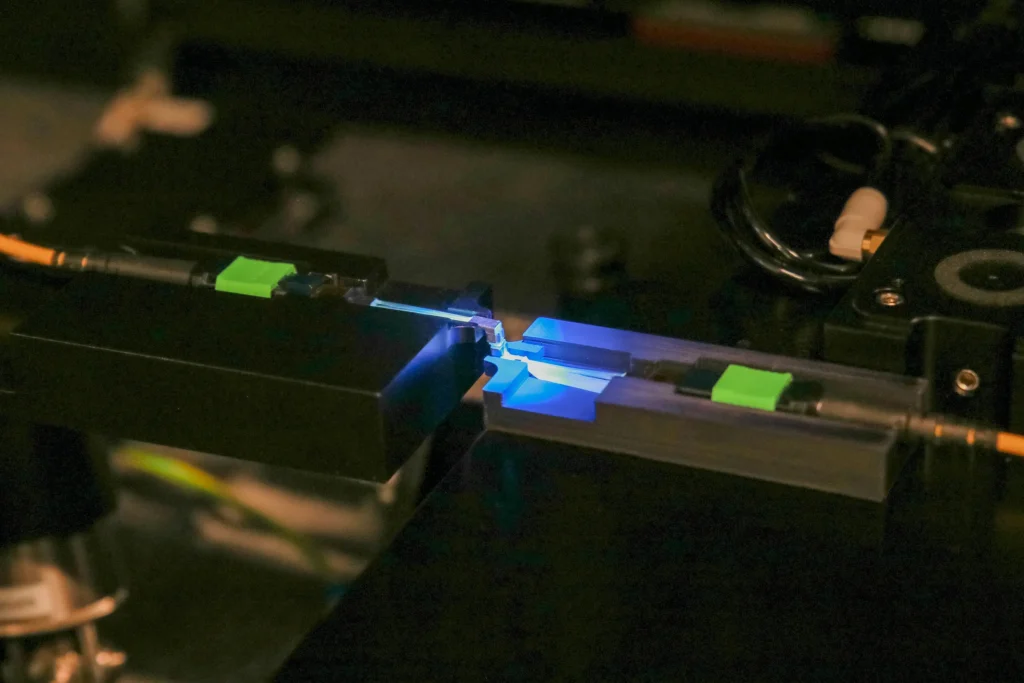

Active alignment for photonics systems

Tresky Automation takes active alignment in photonics systems to a new level. The machine platforms combine nanometer precision, modular processes, and maximum flexibility for research, development, and industrial manufacturing of optoelectronic assemblies.

Large Area Sintern

The integration of large-area power modules is of central importance for e-mobility, as these modules are characterized by high power density and efficiency. Dispensing sinter paste for half-bridge modules (>100 mm²) offers an attractive alternative to stencil printing.

Manual mode

By means of vibration technology, our vibrating feeder feeds components, which are delivered as bulk material, to the processing process. The feeder is designed in such a way that the components are positioned in a vibrating, small open container in such a way that the head camera clearly and precisely recognizes the individual components and automatically transmits the XY coordinates to the bonding head.

We Develop, Produce and Distribute Bonders

The semiconductor market points the way for many other markets and is therefore constantly changing. Thanks to our modular and flexible machine concept, combined with our numerous innovative options, we enable our customers to react quickly to new technologies, product requirements and new market situations.

Latest News and Events

Find out about the latest news and upcoming events from Tresky in the field of DIE bonding technology.