Highest Precision for Optoelectronic Assemblies

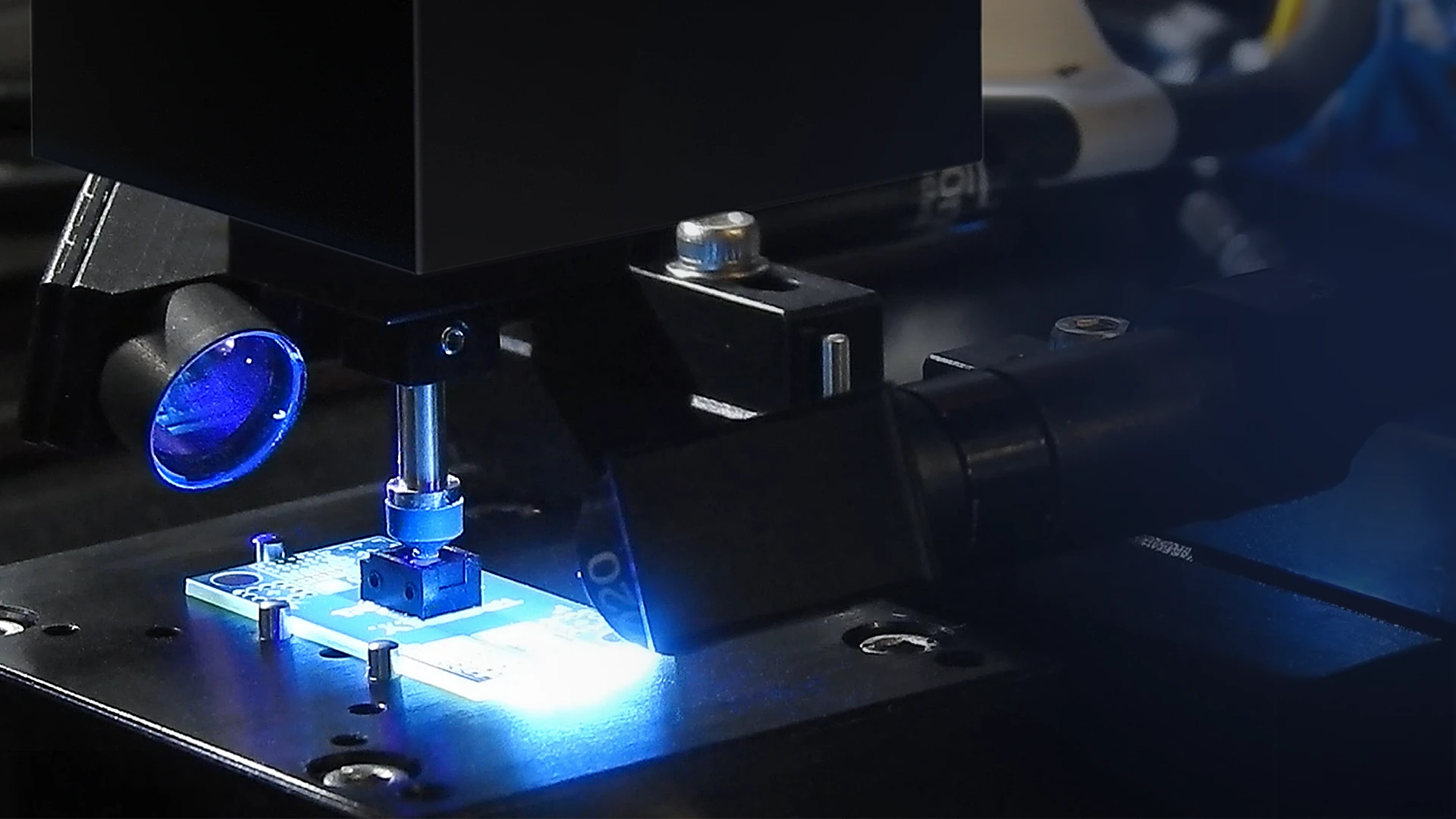

Active alignment of optical components is at the heart of modern photonics manufacturing. Unlike passive alignment, which positions components solely on the basis of geometric features, active alignment uses real-time signal feedback during assembly. This ensures that not only the geometric center is achieved, but also the actual maximum light coupling performance. This is essential for applications with single-mode fibers, silicon photonics systems, or hybrid modules with complex geometries.

Achieve a New Level of Precision with Active Alignment

Photonics is considered a key technology for ultra-fast data transmission, high-precision sensor technology, and forward-looking communication systems. Optical transceivers, LiDAR systems, infrared sensor technology, and quantum technologies require manufacturing processes with nanometer accuracy. Active Alignment from Tresky Automation delivers exactly this precision and maximizes coupling efficiency and yield.

Active Alignment with Nanometer Precision

Tresky relies on high-precision, multi-axis positioning systems for the active alignment of optical components. These enable movements in all six degrees of freedom, translation and rotation along the X, Y, and Z axes, and allow alignments with nanometer accuracy in any direction.

In the Active Alignment process, fibers, chips, lenses, or laser diodes are positioned and optimized in real time using optical feedback signals. The result is maximum coupling efficiency, maximum process stability, and reproducible quality, even for complex optoelectronic assemblies.

Integrated Platforms for Assembly and Connection Technology

Tresky’s modular machine platforms cover the entire process, from precise component positioning and optical alignment to final bonding. Customer-specific requirements and scalability are consistently taken into account. In addition to active alignment, other bonding technologies can also be integrated, such as:

- Tresky Thermocompression Bonder: Reliable Chip/Substrate Bonding Using Heat and Pressure.)

- Tresky Epoxy/Adhesive Bonder: Innovative Adhesive-Based Chip/Substrate Bonding Technology.Ultraschall-Bonding

- Tresky Sintering Bonder: Assembly and Interconnection Technology for E-Mobility Solutions and Power Electronics

- Reliable Direct Contacting of Chips on a Substrate

This universal platform makes Tresky systems unique and offers maximum flexibility without compromising precision and process reliability. All systems can be used in research and development through to industrial series production.

Flyer

Active Alignment

Flexible Coupling Processes from a Single Source

Tresky’s Active Alignment combines nanometer accuracy with flexible mounting methods and supports common coupling methods:

Edge coupling

Light is coupled directly into waveguides exposed on the side; coupling efficiency < 1 dB, ideal for silicon photonics, laser modules, and high-speed optical connections.

Grating coupling (Surface coupling)

Vertical coupling via surface-structured gratings; robust and process-friendly for wafer-level testing and compact optoelectronic modules.

Lensed fiber, lens coupling, and free-space coupling

optical connection without direct contact; for applications with special requirements for cleanliness, vacuum, or long-term stability, e.g., in space travel, high-power lasers, or hybrid opto-mechanical structures.

Loop coupling

Loop coupling uses closed optical structures such as microrings to couple light between waveguides, thereby controlling resonance, filtering, and modulation. This technology enables compact, low-loss, and precisely adjustable photonic components for communication, LiDAR, and sensor systems.

Fiber coupling

In fiber coupling (direct coupling), the light from a laser diode or VCSEL is coupled directly into an optical fiber without an intermediate lens. This precise connection enables efficient light transmission between photonic components and systems. Maximum alignment accuracy in the nanometer range as well as thermal and mechanical stability are crucial. Modern active alignment and bonding technologies minimize losses and achieve long-term stability.

Array Coupling

Array coupling enables the precise coupling of multiple light sources or waveguides in photonic systems. With high positioning accuracy and minimal loss, laser arrays, VCSELs, or fibers are coupled to photonic integrated circuits. This creates efficient, scalable, and low-loss interfaces for high-speed communication, sensor technology, LIDAR, and quantum photonics.

All processes benefit from the continuous signal evaluation and high-resolution positioning movements of our machines.

Added Values

Maximum Precision

Tresky enables nanometer-precise alignment of optoelectronic components through continuous evaluation of optical feedback signals during the assembly process. This ensures that the maximum light coupling performance is achieved and coupling losses are reliably minimized.

Maximum Coupling Efficiency

High-precision multi-axis alignment allows optical components to be aligned in real time so that the full potential of light coupling is exploited and losses are reliably minimized.

Higher Process Reliability and Reproducibility

Active compensation of component tolerances automatically detects and compensates for even the smallest deviations during the assembly process, resulting in stable, reproducible, and fully documentable results.

Flexible Process Integration

The use of high-precision multi-axis positioning systems allows a wide variety of coupling methods to be implemented on a single machine platform. The parallel kinematic multi-axis movement enables high-precision alignment in all spatial directions, allowing various optical coupling strategies to be implemented.

Faster Setup and Cycle Times

Since all movements are performed via a single kinematic unit, complex mechanical changeovers are almost entirely eliminated. This shortens setup times, reduces sources of error, and increases flexibility in the production process.

Future-Proof Manufacturing

Tresky’s Active Alignment solutions can be flexibly adapted to different production volumes, from the production of individual prototypes and pilot series to fully automated large-scale production.

Combined DIE Bonding Processes

Active Alignment can be flexibly combined with numerous DIE bonding technologies from our company. This results in a high-precision, scalable, and reliable complete solution, from optical alignment to final bonding, in a single system.

Learn more about Active Alignment by Tresky