Bonding Processes Using Eutectic Alloys

Eutectic bonding is a process used in microelectronics and microsystems technology to bond components, especially semiconductor chips, to substrates or to connect them electrically. It is a special form of soldering in which the solder is an eutectic alloy. These special solders have significant advantages in connection quality and process control.

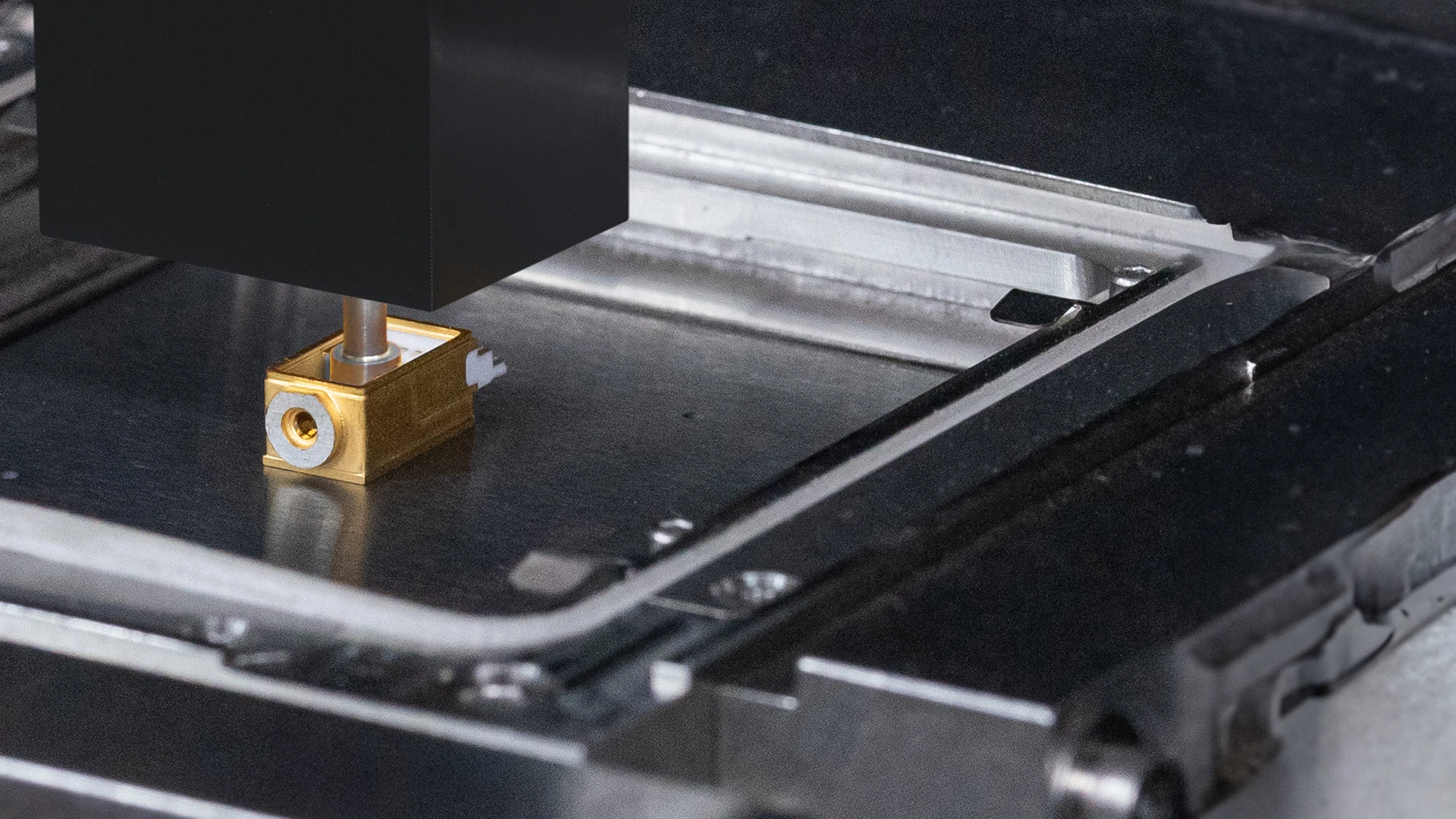

Tresky’s eutectic bonders are used in the semiconductor industry to mount semiconductor chips on carrier substrates or PCBs. They enable very precise alignment and assembly of devices and provide excellent control of process parameters such as temperature, pressure and process gas flow, which is essential for repeatable solder joint quality.

Eutectic bonding connects chip and substrate by means of an intermediate layer to form a eutectic system. This bonding process exploits the specific properties of the individual materials and alloy mixtures during bonding. The frequently used gold/tin alloy (AuSn 80/20) has its melting point at 280 °C, while a gold/silicon alloy (AuSi) finds its melting point at 363 °C.

An eutectic alloy is a mixture of two or more metals or elements in which the melting point of the alloy is lower than the melting point of the individual elements. This means that the alloy melts and solidifies abruptly at a certain temperature. This point is called the eutectic point.

In eutectic bonding, a thin layer of the eutectic alloy is applied to the components to be bonded, e.g. a semiconductor chip and a substrate. They are then heated to the desired temperature to melt the solder. Once the melt is reached, the solder bonds to the components and forms a solid bond when it re-solidifies. Because the melting point is precisely known, the process can be precisely controlled to produce a reliable and permanent bond.

Added value

Precise Alignment

Eutectic bonding enables very precise alignment of components because the melting and solidification of the solder occurs abruptly at a specific temperature. This results in accurate and repeatable component positioning.

Good Electrical Conductivity

Eutectic alloys often exhibit good electrical conductivity. This is particularly relevant in microelectronics.

Good Thermal Conductivity

Eutectic alloys often also have good thermal conductivity. This is critical in applications where heat must be dissipated, as it helps regulate device temperature and prevent overheating.

Miniaturization

Because of its precise alignment and ability to create tiny solder joints, eutectic bonding enables miniaturization of electronic assemblies and microsystems.

Reliability

Eutectic bonding can create durable and reliable connections that can withstand the stresses and environmental conditions to which electronic devices and microsystems are exposed.

Integration of Functions

In some cases, eutectic bonding can also be used to integrate additional functions or sensors into a system by providing a tight bond between different materials.

Low Process Temperatures

Depending on the eutectic alloy, low process temperatures can be used, which is important to reduce material stress on chips or substrates.

Variable Parameters

- Work Holder Temperature

- Collet Temperature

- Ramp Heating and Ramp Cooling