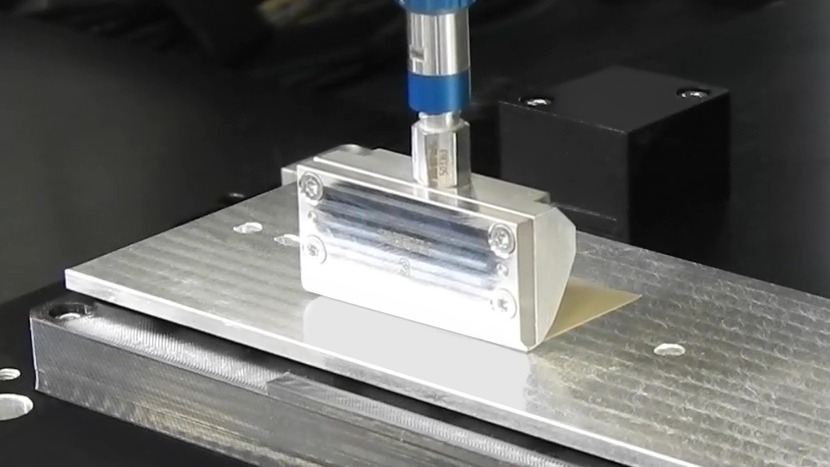

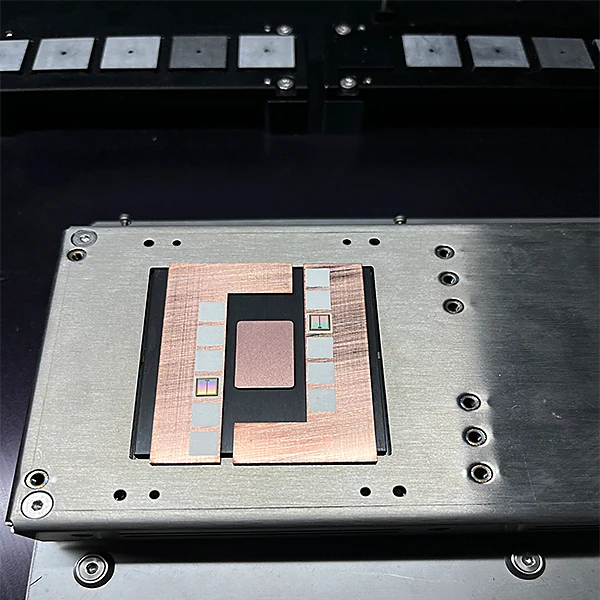

Tresky allows dispensing of over 100 mm² for large area sintering applications

The integration of large-area power modules with an area of over 100 mm² is highly relevant. These modules are of great importance for various applications in e-mobility, as they offer high power density and efficiency. However, connecting these components is challenging. Tresky GmbH from Berlin is presenting dispensing for Large Area Sintering at PCIM Europe […]

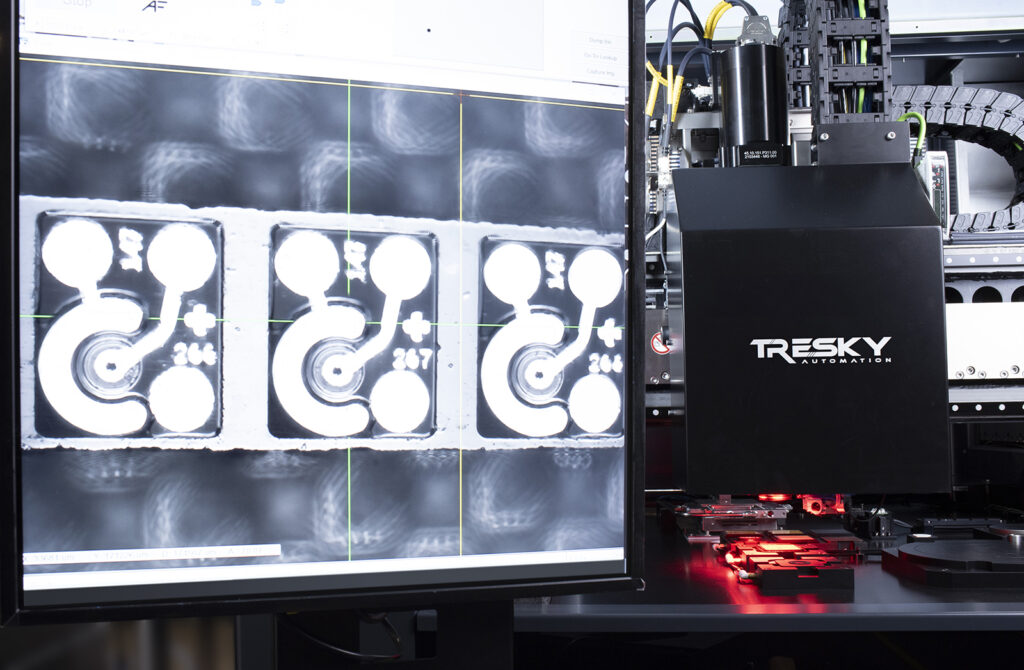

Manual mode for maximum control and flexibility with DIE bonders

The DIE bonders from German specialist Tresky are equipped with a flexible, manual mode. This reduces the entry barrier for new users and makes it possible to achieve reliable die bonding results within a very short time. The manual mode is particularly suitable for applications that require quick iterations and adjustments while keeping highest precision. […]

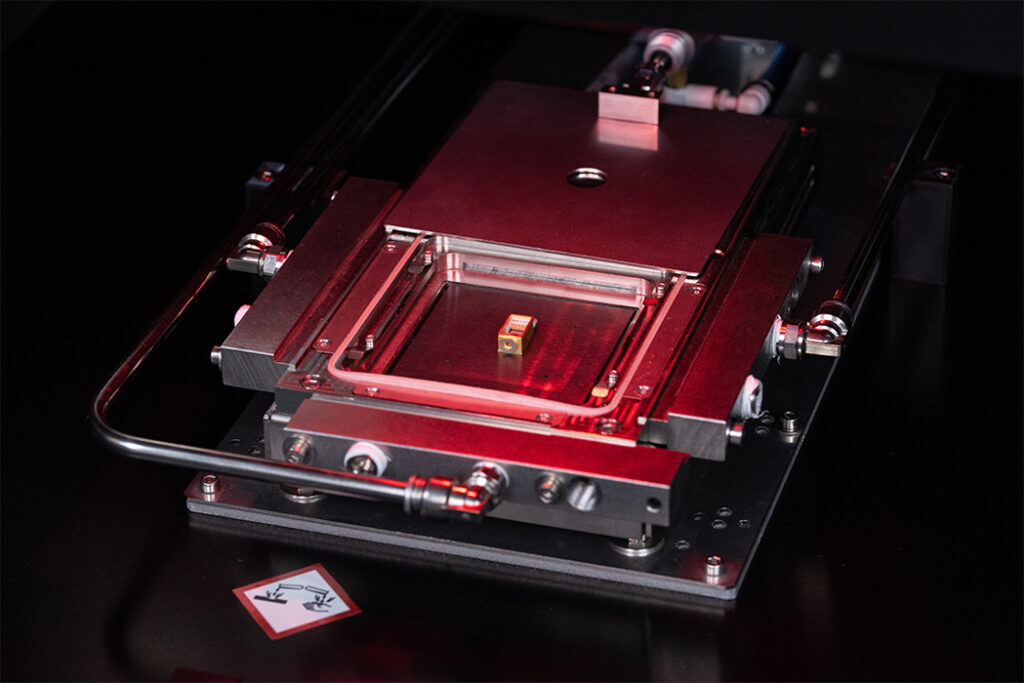

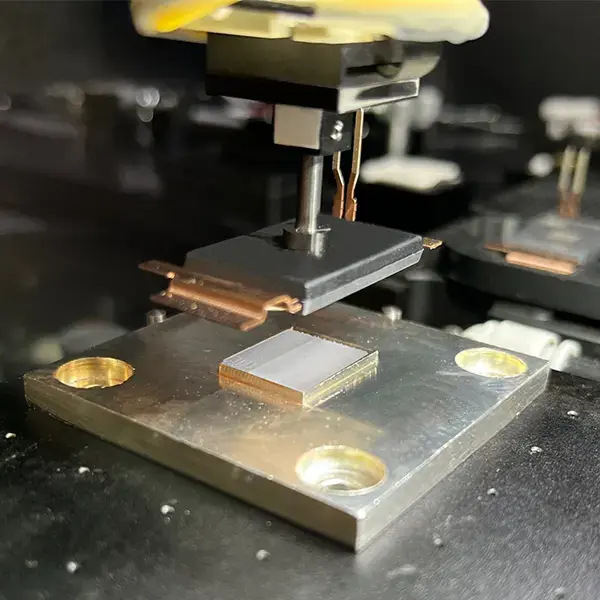

Fluxless soldering using formic acid vapor for optoelectronics

Soldering using formic acid vapor in combination with nitrogen (HCOOH + N2) offers significant advantages in assembly and connection technology for applications in optoelectronics and photonics. Especially in the field of sub-micron bonding, Tresky has introduced several innovations in recent months and is now presenting the formic acid module for reliable use in bonding processes at productronica 2023.

Tresky Automation launches new website

The German DIE Bonder specialist is launching its brandnew website with a fresh corporate design for productronica 2023. The new website includes different focus and structure for the bonder solutions, which should help selecting proper information.

Tresky unveils its latest breakthrough product at productronica 2023: the photonics bonder for sub-micron use in nano- and optoelectronics

The German DIE Bonder specialist Tresky GmbH is excited to introduce its latest product the highly precise photonics bonder at productronica 2023 in Munich. The recently developed bonder is based on a new machine concept. The stable granite base, makes it one of the most precise placement systems on the market. This level of precision is indispensable, especially for use in nano- and optoelectronics.

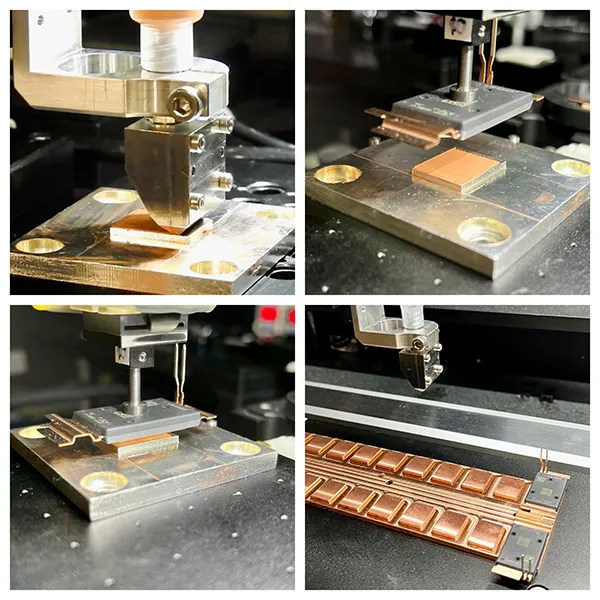

Tresky presents metallic sintering for power electronics at productronica 2023

Tresky GmbH from Hennigsdorf near Berlin will present various metallic pre-sintering processes, including the Die Transfer Film (DTF) process, at this year’s productronica 2023 in Munich. Especially for bonding semiconductors such as IGBTs, SiC MOSFETs or GaN HEMTs with Ag on DBC or AMB substrates or for connecting power modules on heat sinks, metallic sintering offers a high-performance solution with maximum reliability.

Tresky expands digital service support with Pink Flamingo

The Pink Flamingo document management and support system offers a wide range of possibilities for servicing machinery and equipment. Tresky GmbH uses Pink Flamingo and therefore has the possibility to efficiently provide information and instructions about the Tresky-DIE Bonder to customers. These in turn can access it quickly and easily. In addition, supporting services can also be accessed digitally while saving time.

Electronic low-voltage drive module with multifunctional high-current circuit carrier

Tresky GmbH is part of the ProMuPower project at Kiel University of Applied Sciences, which focuses on the development of high-performance power modules and the associated manufacturing processes. The power modules are being developed for the generation of sustainable energy and for use in electromobility.

Sintering as a key technology for the energy transition and e-mobility

Assemblies with high-performance semiconductors are key components for the global energy transition and electromobility. For this reason, Tresky GmbH from Hennigsdorf near Berlin has been working on this key technology for some time and will present further product and process innovations in 2023 as part of additional development steps.

Highest machine precision thanks to Mother Nature

Particularly when it comes to the highest precision requirements, machine builders from different industries like to rely on a material that is thousands of years old, from the depths of the earth: granite. Particularly when the components to be processed are extremely small, precision comes into even stronger focus, as in the semiconductor industry with DIE bonding.